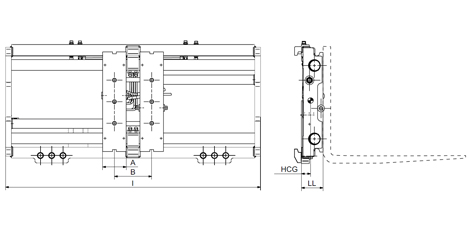

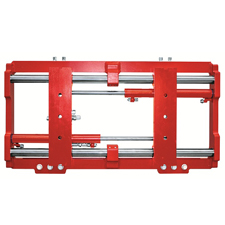

Suitable for light, normal and heavy duty applications, the robust chassis has optimised visibility on all working levels.

Used to accurately handle palletized loads.

Suitable for light, normal and heavy duty applications, the robust chassis has optimised visibility on all working levels.

Used to accurately handle palletized loads.

Range: 2500 Kg - 14500 Kg

Plus: